Training courses from Maintenance Troubleshooting International are offered in three formats. See our course syllabus sheets for the applicable formats. Class formats offered are:

MTI Hands-On Center

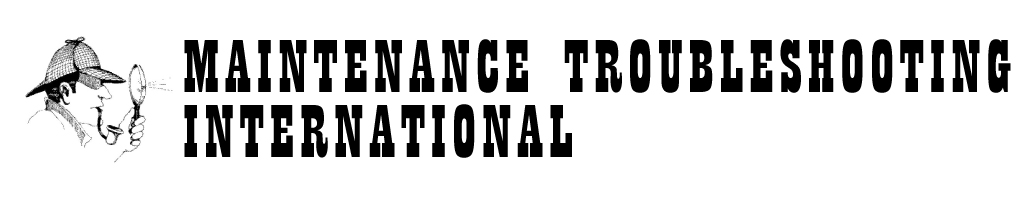

These courses are taught at our hands-on training center located at 2860 Ogletown Road, Newark, DE 19711. The training center has over $200K worth of full size industrial equipment to allow “hands-on” work. Classes offered in the training center are, for the most part, dedicated to a “hands-on” approach. When the course involves a large percentage of “hands-on” activities, the class attendees will spend time turning wrenches, using precision measurement instruments, taking meter readings and using shop issued tools to tear equipment down and rebuild it. When actual “hands-on” activities aren't possible (examples: boiler training, cooling tower training), we supplant our classes from our 287+ title video library to provide a real time view of mechanics performing “hands-on” work in a field situation.

The use of full size industrial equipment to work on as well as a fully equipped maintenance shop allow the attendee to perform tasks that perfect their skills in an environment where time can be taken to cement the learning for future use.

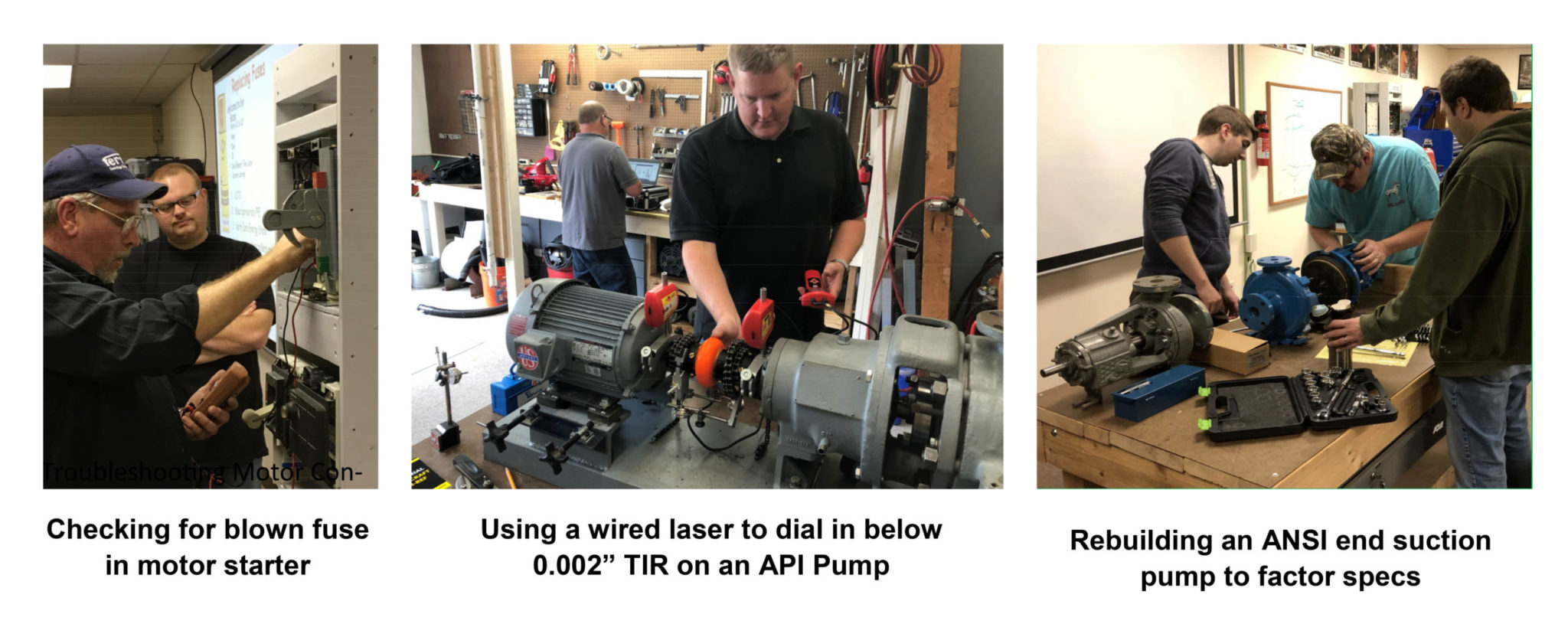

COVID Safety at the MTI Hands-on Training Center:

ZOOM Interactive

Zoom Interactive is our completely unique approach to virtual training—an industrial FIRST from our company.

Requirements:

- Computer/Tablet with camera & microphone

- Free version of Zoom software

Our training center has been set up as a video broadcasting studio with large screen monitors, remote controlled state-of-the-art Aver cameras, and a close work camera for detailed views of mechanical and electrical assemblies. Attendees sign on to a typical zoom meeting and interact with the instructor throughout the class. Class attendees are required to have a computer or tablet with camera and microphone capabilities and internet access as these are live classes. Simply download the ZOOM program onto the device you plan to use and set up your camera and microphone and you’re ready for class. Once you register for your class, an email from MTI provides a link to sign on to the class and participate. In many of our classes, workbooks, class worksheets, books and even FREE tools are sent to the attendee in advance so they may participate in hands-on activities with the instructor at various points during the classes. For example, participants for our ZOOM Interactive bearing class receive: full size bearing sheets, bearing ID scale, 0-1” Vernier Micrometer, inspection shims, a class book, worksheets, desk exercises, Audel Mini-Ref, and a large bearing wall chart to keep as part of the class as well as some additional returnable materials when necessary. All materials and books are sent out about two weeks before the class is scheduled. During classes the instructor will actually accomplish “hands-on” activities if possible, showing pre-set examples using the Aver camera, as well as showing segments of industrial videos from our library that bring field situations into the classroom.

One interesting element of the ZOOM Interactive format is the ability to show class participants real examples of failed components of both mechanical and electrical machinery from our cataloged collection of these items. If you can’t attend a class at the MTI hands-on center, it’s as close to being there as you can get.

On-site Training

Our version of a traveling road-show.

Requirements:

- A quiet classroom

- Screen for a projector or large flat screen monitor

- Minimum 6 trainees

- Tables with a capacity of at least 300#, able to handle typical maintenance tools &/or equipment