Hydraulic Fluid Power

Fluid Control

Course Number: HFP-303

Course Description:

This industrial hydraulics course is designed to enhance the ability of the Mechanical Maintenance worker to accurately troubleshoot and repair Hydraulic System problems. This goal is achieved through teaching the participants what each component of a system does and how to troubleshooting these components in a system. Also, to aid in the understanding of the sequence of operation of a system, student are shown how to read Hydraulic schematics allowing them to narrow down the problem area to a unique set of or even one single component as the most likely cause. Our training stands offer an opportunity to build simple and more complex hydraulic circuits as well as plenty of opportunities to troubleshoot problems and get the system working again. A fantastic opportunity to learn hydraulics in just three days.

Each student will receive class books, work activity sheets, self-test progress evaluations, as well as questions from the instructor to make sure they understand the material presented. It is expected that an attendee will leave the class with the basic knowledge of the subject and possess new found skills to better equip them when they return to their job. A certificate suitable for framing will be issued to each attendee who successfully completes the course.

Free Materials included:

Womack Hydraulics Book

3-day course: $1395 per person

Course Syllabus

BASIC HYDRAULIC PRINCIPLES

· Pressure & force

· Advantages & disadvantages of Hydraulics

· Physical properties of liquids

· Pressure Measurement, Vacuum, Compound and Pressure Gauges

· Bernoulli’s Principles, Pascal’s Law

· Horsepower, torque & Electrical Relationships

TROUBLESHOOTING – BASIC REQUIREMENTS

· Component function and operation

· Hydraulic symbols; Reading and Understanding

· Hydraulic Prints; Using Plant-specific prints where

· Available, hands-on written exercises

HYDRAULIC PUMPS

· Positive-displacement of pumps

· Variable volume and Pressure Compensated Pumps

· Gear, Vane, Piston and Screw Pumps

· Troubleshooting cavitation, air entrainment

· Hands-on written calculations of heat developed, stroke and volume

FLOW, PRESSURE, & DIRECTIONAL CONTROL VALVES

· Flow controls, actuator speeds

· Relief/sequence/counterbalance and brake valves

· Pressure-reducing valves

· Solenoid, cam and manual joy stick valves

· Pilot operated valves and pilot chokes

HYDRAULIC CYLINDERS

· Single & double acting cylinders, Seals

· Cylinder types & construction

· Flow calculations for cylinders, stroke, volume and speed

· Regenerative circuit

· Troubleshooting cylinders

HYDRAULIC MOTORS

· Speed & torque

· Types & sizing of hydraulic motors

· Hydraulic motors in circuits

· Flow calculations for motors, volume and speed

ACCUMULATORS

· Applications, sizing. & charging; Gas precharge pressure

· Installation & operating instructions

HYDRAULIC FLUIDS

· Properties & types fluids; Temperature limits of hydraulic

· Fluids

· Fire resistant/biodegradable fluids

· Fluid storage & handling

· Fluid velocities, Friction/restrictions in fluid lines

RESERVOIRS, HEAT EXCHANGERS, & FILTERS

· Contamination control

· Suction Strainers, suction pressure

NOISY PUMPS OR CAVITATION & AERATION

· Low Pressure/Entrained Air

· Vacuum, Foaming. & Air Leaks

LOW, ERRATIC, OR NO PRESSURE

· Wrong rotation of pump

· Relief valve or compensator

· Low reservoir level

· Contamination in valves

TROUBLESHOOTING

· Malfunctioning pumps

· Lack of pilot pressure

· Incorrect plumbing connections

· Solenoid problems

· Wrong temperature or motor speed

· Amperage readings and Pump Working Load

NOISE CONTROL

· Lower noise generation

· Isolating noise

CYLINDER & CIRCUIT PROBLEMS

· Erratic or jerk motion, Blown rod seals, cylinders, or plumbing

· Cylinder drift and Directional Control Valve leakage

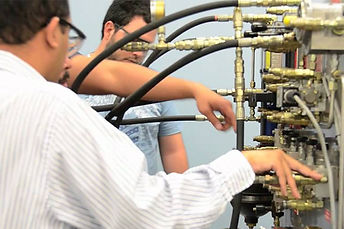

Course Pictures

Hydraulic Work Station: